パターン化フローセル技術

特徴的かつ規則化されたナノウェルデザイン

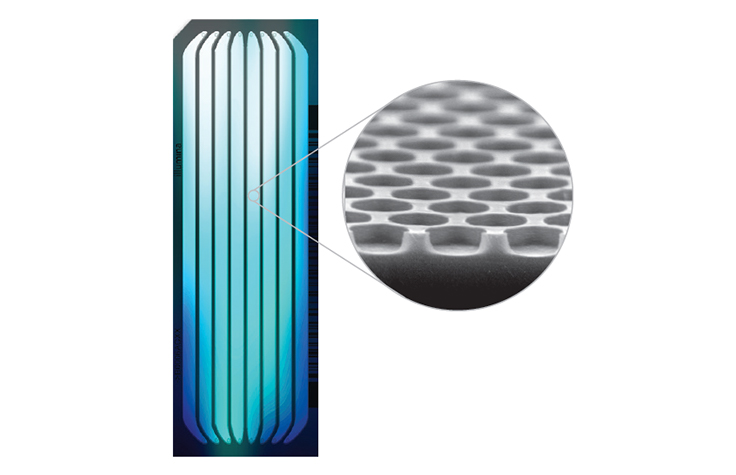

パターン化フローセルには数十億~数百億個のナノウェルがあり、フローセルの両表面の規定位置に配置されています。構造化された配列により、シーケンスクラスターの間隔が均等になり、パターン化されていないクラスター形成よりも多くのメリットが実現できます。

- クラスターはナノウェル内でのみ形成されるため、フローセルが過負荷の影響を受けにくく、より広範なライブラリー濃度に対する耐性があります。

- 正確なナノウェルの配置により、クラスター部位をマッピングする必要がなくなり、各シーケンスランの時間を節約できます。

- クラスター密度が高いほど、フローセルあたりのデータ利用率が高くなるため、シーケンスランのギガベース(Gb)当たりのコストを削減できます。

Prearranged Cluster Distribution on the Flow Cell

Patterned flow cells are produced using semiconductor manufacturing technology. Starting with a glass substrate, patterned nanowells are etched into the surface for optimal cluster spacing. Each nanowell contains DNA probes used to capture prepared DNA strands for amplification during cluster generation. The regions between the nanowells are devoid of DNA probes.

The process ensures that DNA clusters only form within the nanowells, providing even, consistent spacing between adjacent clusters and allowing accurate resolution of clusters during imaging. Maximal use of the flow cell surface leads to overall higher clustering.

Exclusion Amplification Chemistry

Our proprietary exclusion amplification clustering method further increases data output. Exclusion amplification allows simultaneous seeding (landing of the DNA strand in the nanowell) and amplification during cluster generation, which reduces the chances of multiple library fragments amplifying in a single cluster. This method maximizes the number of nanowells occupied by DNA clusters originating from a single DNA template, increasing the amount of usable data from each run.

Advanced Systems Featuring Patterned Flow Cell Technology

Patterned flow cell technology makes data-intensive applications more cost-effective. The NovaSeq X and NovaSeq X Plus systems unite the latest high-performance imaging with the next generation of Illumina patterned flow cell technology. The updated NovaSeq X series flow cell design further reduces the spacing between nanowells, significantly increasing cluster density and data output.

NGSによるハイスループットのプロテオミクス

マルチプレックスプロテオミクスを次のレベルに引き上げ、イルミナのシーケンサーを使用してタンパク質バイオマーカーを発見する方法をご覧ください。

ウェビナーを見る